What is a Pre-Shipment Inspection?

PSI, abbreviation of Pre-shipment Inspection is also called FRI (Final Random inspection) by some inspection companies. This inspection, the most important and popular service in Inspection activity, aims to guarantee the conformity of production to your specifications and international standards.

A Pre-Shipment Inspection from an independent third party gives you the peace of mind that your order has been filled successfully before it is dispatched. Today’s globalized marketplace offers amazing opportunities, but also presents real risks. When working with a supplier overseas it’s critical to ensure the specifications you’ve agreed upon are in fact met. Mitigate the risk of an improperly filled order by taking the necessary precautions.

- Ensure that your order was filled successfully, before it’s dispatched

- Verify quality at the source and don’t pay for defective goods

- Rest assured that the supplier has met all agreed-upon specifications

- Mitigate costly import risks

- Avoid returns and protect your brand’s image

AiT will inspect the selected samples at random against your specifications and approved/ref. samples. This inspection involves a close examination covering such items as construction, workmanship, color, odor, measurement, weight, function, assortment, packaging, labeling marking, etc. the FRI takes place after your merchandise has been 95%(as usually 5% of increase/decrease is allowed) produced and at least 80% of the shipment packed.)

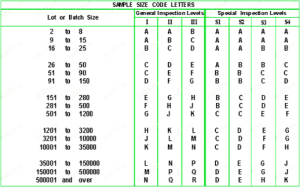

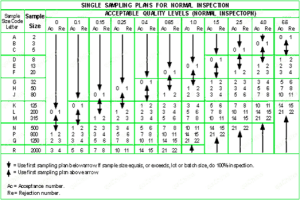

The scope of this inspection consists of the quantity, packaging, quality, marking, and the other important points requested by the clients and international standards. This inspection should be carried out in general in the factory of seller, according to the standard ANSI/ASQ Z1.4-2008 AQL (Default Lever 2.) (see below 2 tables)

For more information, please contact us!