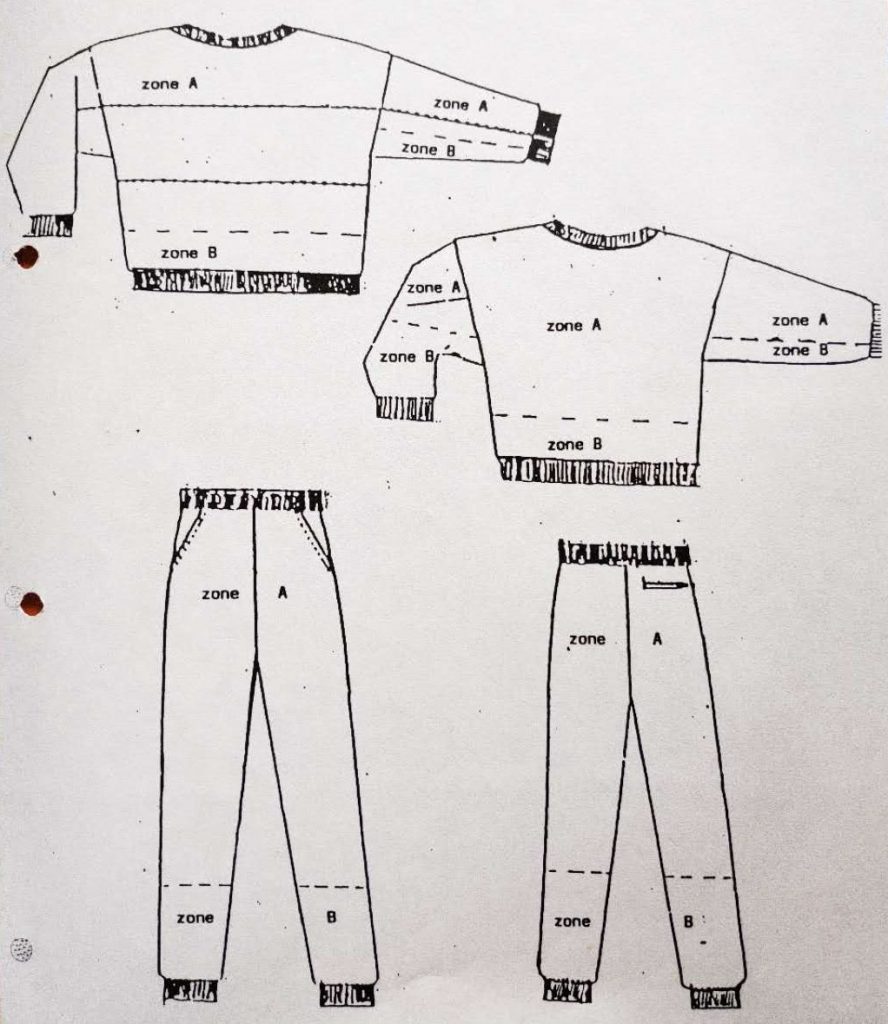

Garment Zoning for Garments Visual Inspection

When perform garments visual inspection for make and workmanship the defects found can be categorized as Critical, Major, Minor defects. In fashion industry, Critical defects are defined as a defect that is likely to result in hazardous or unsafe conditions for an individual in using the product. And that does not meet the mandatory regulations is also critical defect. A critical defect in clothes may cause accident to the wearer and may malfunction when the wearer out wearing a garment with a critical defect on. Anything which can harm the wearer of the product are critical defects. If a critical defect is found in an order, it is definitely failed. Because the definition of critical defects is very clear and easy to be classified. There are few cases with confusion about critical defects among all parties in quality control practices.

But as per Major and Minor defects in the garments visual inspection, it is not enough to know the definitions only.

Why Zone A and Zone B for garments visual inspection?

A Major defect is one that is likely to create failure of the unit for its intended purpose. Therefore a garment with a major defect is likely to result in a customer complaint or return. A major defect is also one that will most likely result in product failure after a period of time that is considered unacceptable to the customer or end user. A major defect will usually (but not always) be obvious to the inspector during the garments visual inspection. It will also be obvious to the customer during use.

A Minor defect is a discrepancy from the standards, but one that is not likely to affect the usability of an object. Therefore A garment with a minor defect is unlikely to result in customer complaint or return. A minor defect is a deviation from the required standard, but that is unlikely to affect the usability of the product. A minor defect will usually be seen by the inspector, but may be overlooked by the customer.

What is WHHW?

Whether a defect is a major or minor, you should judge it by its affect from several factors. They are what it is, how big it is, how it happened and where it is. I call it WHHW.

In some cases, a major defect can be considered as minor based on the location of the defect in a garment, vice versa. This location is called as a Zone. Garment zoning is done for fair evaluation of the garment during the visual inspection. For most practices, the way of Zone A and Zone B is mostly accepted by most garment clients. But there are companies who zoning as Zone A, Zone B and Zone C. That is not very common and less practical, and I do not recommend.