Lad dips approving helps to quality of bag?

Why does approving lad dips not help to control quality of bag?

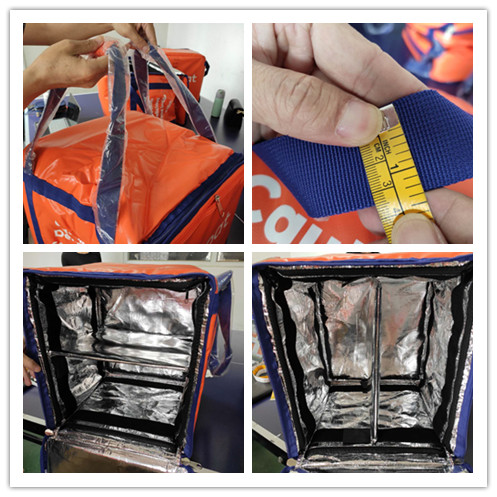

Quality of bag is by colour, design, material and makes

I do not know why some customers require to approve lab dips to control colour quality of bag? Because most lab dips are without any finishing. Even if customer has select the best colour among the lab dips, it surely will change a lot after waterproof finish and pvc coating finish. It causes confusion, as well as cost time(I think usually the factory cost 3 days to do it, sending to exporter for looking at 3 days, and then sending to customers for 4-5days, and cost 1-3 days to approve).

More than that, it confuses the customer, get the question why the colour always changes.

we are guessing why this situation occurs, may caused by previous experience and orders, they have found too much colour shade variations, they want to help factory to control it by approving the whole process.

I do not think it is a good way, some cases may become worse by this way.

What we should do is try to avoid it from the root-the fabric suppliers.

I suggest that when customer gives them a colour sample(please give sample as large as you can. As too small sample is hard to compare with), they should produce a large sample with all finish on for approve. You only approve the colour one time-the colour after finish. You do not need approve any middle process, it is the responsibility of fabric supplier to control it. And the exporter salesman should have the common sense to evaluate the colour shade variation, if the colour is not acceptable by himself, it is not acceptable for customer either. This will make the process simpler and shorter. More than that, it saves much time from the lead time.