How to make Masks Quality Inspection?

How to make Masks Quality Inspection?

Making masks quality inspection includes lab testing and visual inspection 2 aspects. To make good control of the quality of masks, firstly you must know the categories of masks and the structure of a mask. Actually there are many kinds of categories for masks. Basically it can be categorized by below methods:

- According to material used, there are cotton mask, PP non-woven mask, active carbon mask, polymers mask etc.

- For differnt purposes, there are surgical mask, normal mask

- According to shapes, there are flat mask and 3D mask

No matter what kind of categories it is, the function of a mask is to filtrate the air through so as to protect the wearer. Removing most of the dust and aerosol, which proved to be one of the propagation mode. The other two kinds of propagation mode crowd intimate contact dissemination has also been proved. Therefore I take the most common mask, flat surgical mask for example.

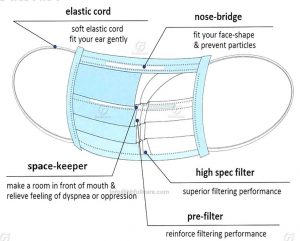

You will see there are 3 layers of non-woven fabric in a mask. Inner layer is normal PP non-woven fabric, to absorb the moistures from the mouth of the wearer. Outer layer treated with waterproof, is to prevent liquid spattering. However, middle layer is the most important. Because it is PP melt blown non-woven fabric after Polarization, as a protective screen to prevent viruses.

In one word, minimum filtering effect is a key parameter testing in the relevant lab. While Toxic residue testing is an alternative.

Masks Quality Inspection

Now I will introduce the way to inspect the visual part of masks, as an important part of masks quality inspection.

- Size of mask. Two sizes of mask as standard. 19*9 cm for adults and 15*9cm for children. Besides the length and width of the mask, you should also measure the length of elastic cord and the stretched length of elastic cord. As the mask turns flat to 3D when it is worn, the expanded curved width should be measured against specification to make sure there is enough room for the wearer’s mouth.

- The check list of masks: 1) the surfaces of mask should be even, no broken, no patches, no foreign materials; 2) the ultrasonic sewing seam or heat-sealed seam is secured; 3) the nose bridge is not missing; 4) No other cosmetic defects on.